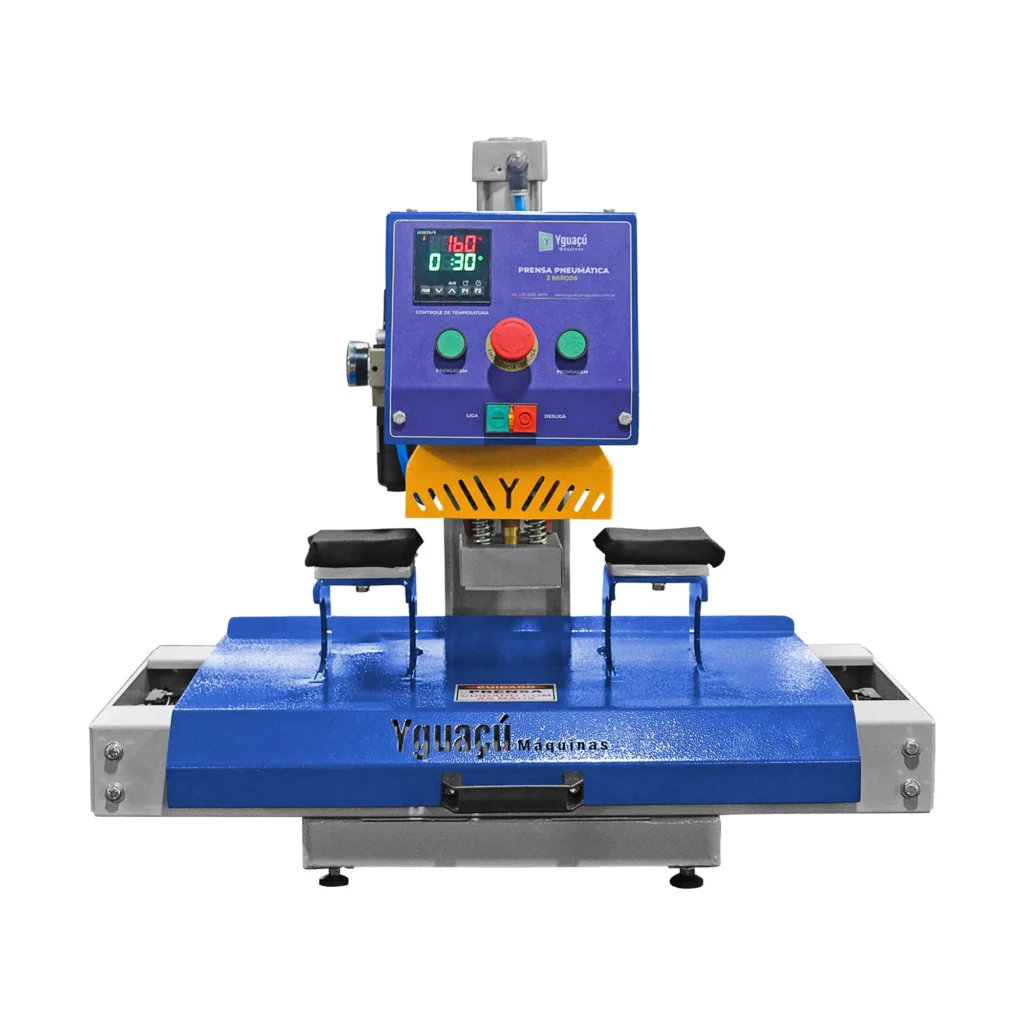

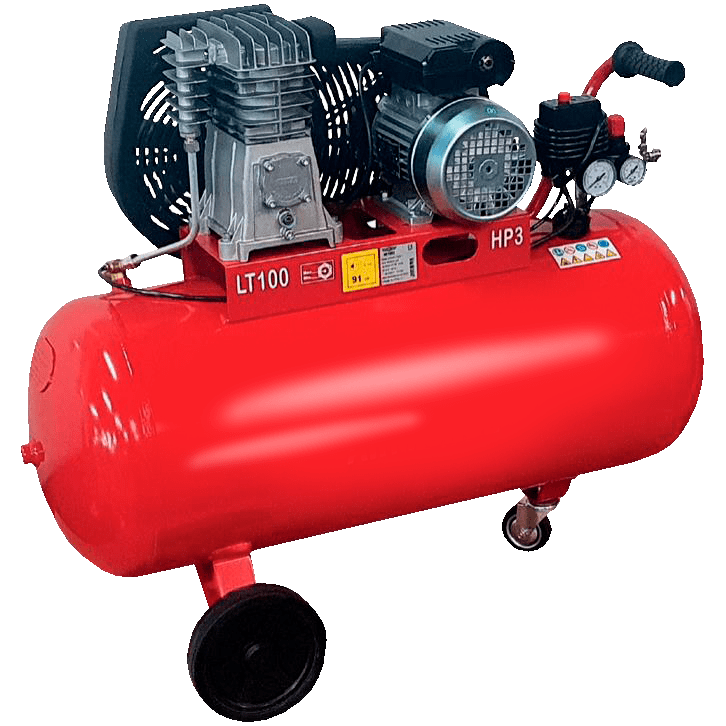

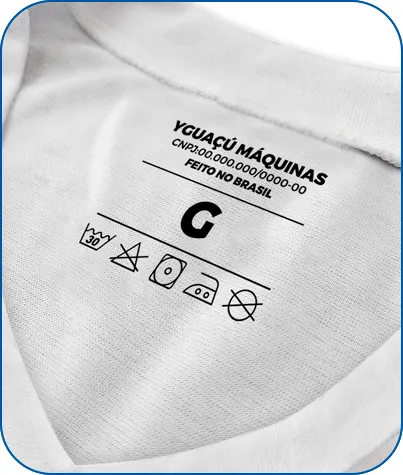

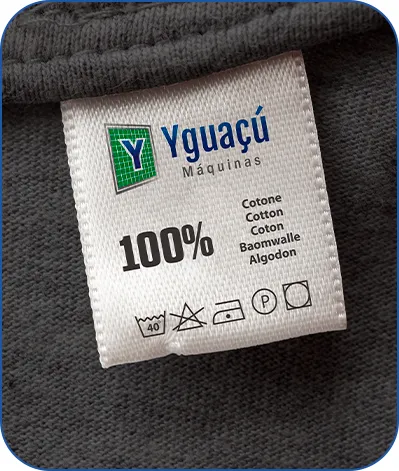

The Pneumatic Press with Two Cradles is a robust piece of equipment designed for applying labels and heat-setting processes on textiles. Pneumatic operation ensures uniform pressure and a standardized finish, ideal for the apparel and personalization sectors. It features two work bases that allow for simultaneous positioning of parts, optimizing operational flow and increasing productivity. The printing area is available in two options: an aluminum heating cradle in sizes of 10x10cm, 15x15cm, or 20x20cm, depending on production needs. The heating system is fast and efficient, ensuring temperature stability for different applications. Its compressed air operation provides agility, uniformity, and precision in the process. Main applications include label application, DTF (Direct to Film), sublimation, transfer printing, screen-printing curing, and other heat-setting processes on fabrics. With a production capacity of approximately 150 pieces per hour, it is a practical and reliable solution for increasing production line performance.

- +55 43 3338-8879

- [email protected]