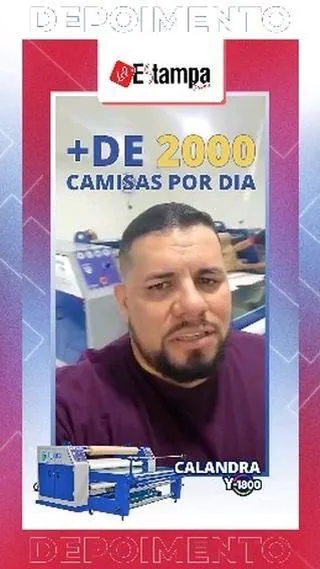

The Y-1800 Thermal Textile Calender represents a significant advancement for the large-scale printing sector, producing an average of 4,000 pieces per day, offering an optimized combination of high productivity and operational simplicity. In an increasingly competitive market demanding fast delivery times and superior quality, adopting efficient technologies like the Y-1800 Calender becomes not only an advantage, but a necessity for companies that aim to stand out.

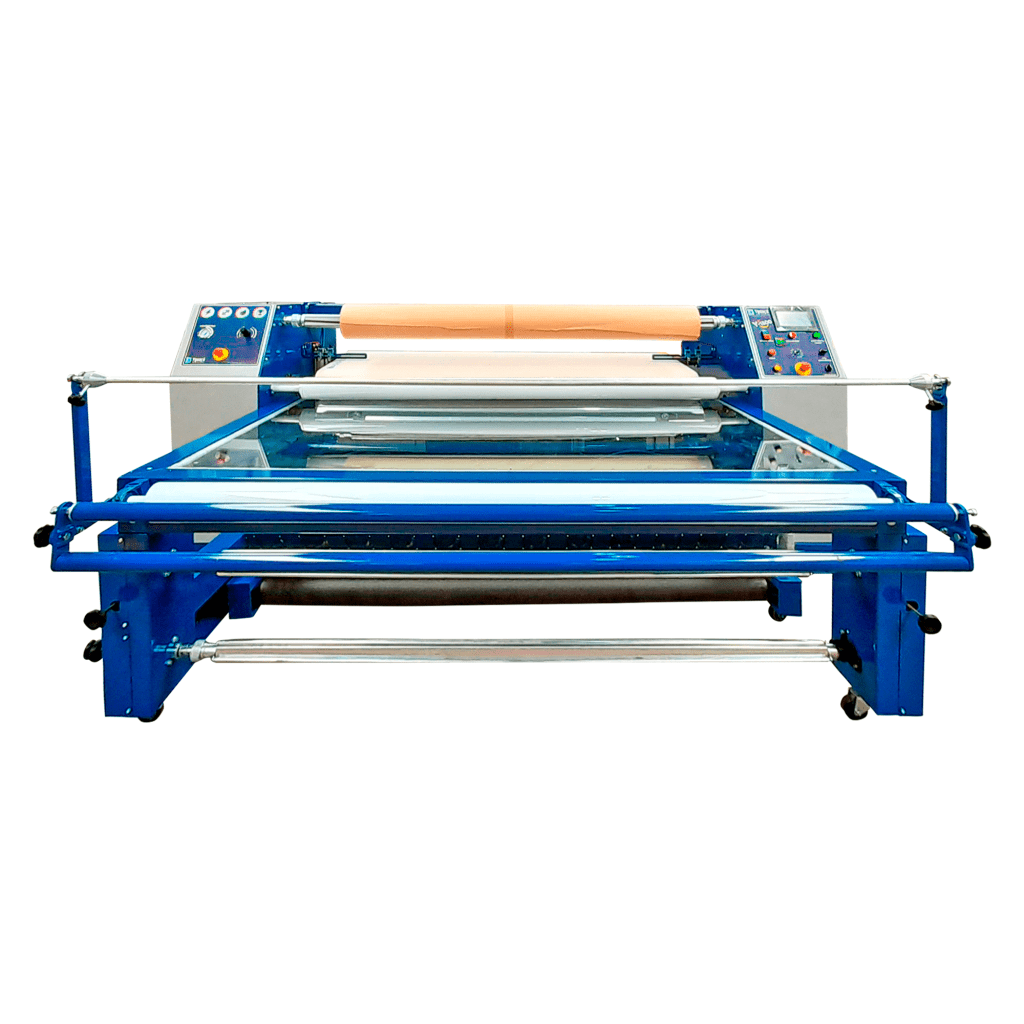

With an impressive working width of 1800mm, equivalent to 71 inches, this equipment was meticulously designed to meet the demands of large-scale production. Its ability to process large fabric formats continuously and uniformly eliminates the bottlenecks often associated with the use of multiple smaller heat presses. This feature alone introduces a new dynamic to the printing workflow, enabling ambitious projects to be completed with greater agility and consistency.

It delivers high image quality when transferred to fabric, fidelity, vivid and durable colors and no unwanted deformations.

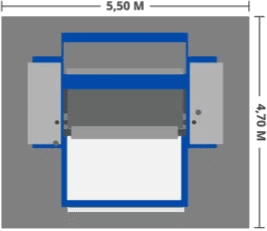

Replacing multiple large-format heat presses with a single Y-1800 calender brings with it a number of tangible benefits. First, the optimization of physical space is notable. The area previously occupied by various pieces of equipment can be reallocated to other stages of the production process, such as material preparation, quality control, or packaging, contributing to a more efficient and organized factory layout. This space savings is particularly valuable in industrial environments where square footage is at a significant cost.

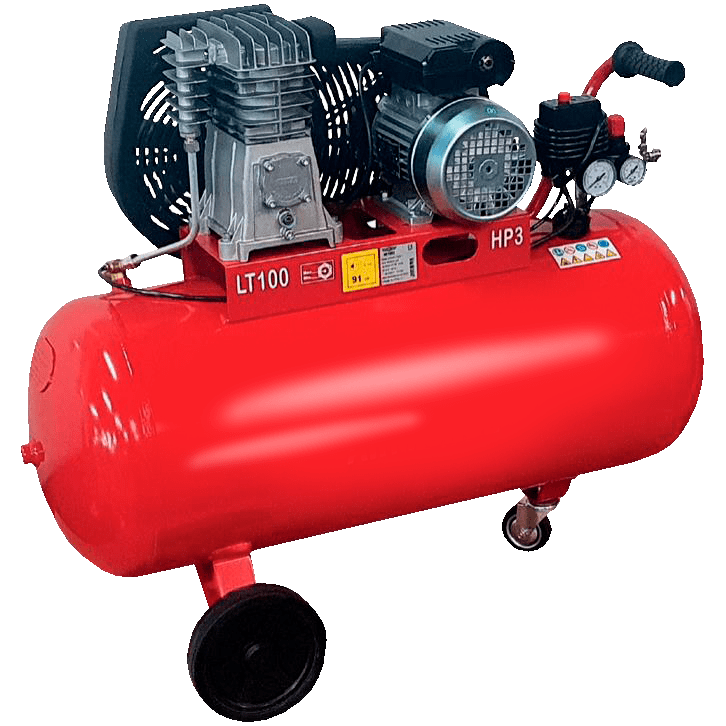

In addition to optimizing space, the Y-1800 Thermal Textile Calender also provides a substantial reduction in operating costs. Operating a single piece of equipment, compared to multiple presses, results in lower energy and consumable consumption, a reduced need for corrective and preventive maintenance, and, crucially, an optimized workforce involved in the print transfer process. Fewer operators can supervise and manage production, resulting in a leaner payroll and greater efficiency per employee.

Ease of operation is another strong point of this ironer. Designed with intuitive interfaces and accessible controls, the Y-1800 allows operators to quickly adapt to its operation, minimizing training time and increasing the autonomy of the production team. This simplicity does not compromise the precision and quality of the final result, ensuring vibrant, durable prints with excellent adhesion on a wide range of fabrics.

The versatility of the Y-1800 Thermal Textile Ironer is also noteworthy. It can work with a wide range of textile materials, from natural fabrics like cotton and linen to synthetic fibers like polyester and nylon, adapting to the diverse needs of the printing market. Whether for the production of apparel, decorative items, promotional materials, or technical fabrics, the Y-1800 delivers consistent, high-quality performance.

In short, the Y-1800 Thermal Textile Calender is not just a piece of equipment; it's a strategic solution for large printing companies looking to increase their productivity levels, optimize their resources, and reduce their operating costs, while maintaining ease of operation as a key differentiator. Its robustness, capacity, and intelligent design position it as a high-value investment for companies aiming for growth and competitiveness in the textile market. The transition to technology like the Y-1800 represents a firm step toward a future of more efficient and cost-effective production.