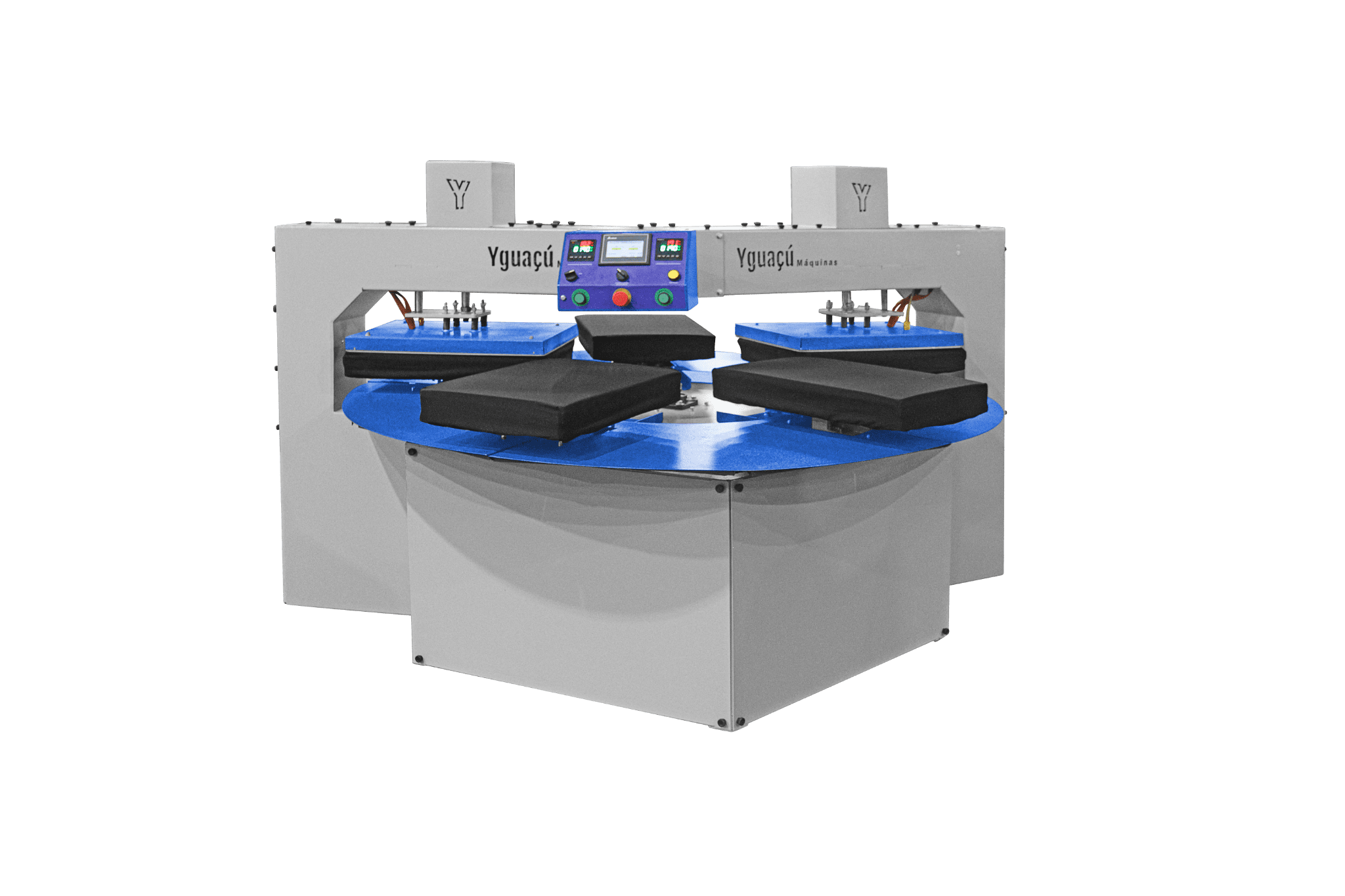

New Launch: Automatic DTF Carousel Heat Press

Yguaçú Máquinas has just introduced to the market a launch that promises to transform the routine of those who work with digital printing and heat transfer: the Automatic DTF Carousel Heat Press.

Designed for high productivity and versatility, it was developed especially for the DTF (Direct to Film) process, but also adapts perfectly to other techniques, such as sublimation, transfer, and screen printing curing.

Why is this launch so innovative?

- Intelligent carousel system: with 5 positioning bases, allows continuous production flow and eliminates downtime.

- Dual heating stations: two independent aluminum plates, fully programmable for time and temperature.

- Automatic rotation by electric motor: more agility, precision, and operational comfort.

- Touch Screen Display: simple and modern interface to program the equipment

- Intelligent carousel system: with 5 positioning bases, allows continuous production flow and eliminates downtime.

- Dual heating stations: two independent aluminum plates, fully programmable for time and temperature.

- Automatic rotation by electric motor: more agility, precision, and operational comfort.

- Touch Screen Display: simple and modern interface to program the equipment

Impressive Productivity

Impressive Productivity

With this launch, your production gains a new pace:

- Up to 360 pieces/hour (with 1 press per piece).

- Up to 180 pieces/hour (with 2 presses per piece).

The Impact on Printing

In practice, the Automatic DTF Carousel Heat Press represents a technological leap for companies that want to stand out in the customization market.

- Allows scaling the business without needing to proportionally increase the team.

- Raises the quality standard, as automation reduces manual errors.

- Provides more competitiveness, allowing you to take on large orders with confidence.

Technical Specifications

Network Types

220v

Single-phase, Two-phase, Three-phase

380v

Three-phase

Power

10.000W

Weight

550kg

Application

DTF, Sublimation

Product Dimensions

For Transportation

220x160x130cm

Minimum for Installation

25m²

Printable area

40×50 ou 50x70cm

A Solution Made for the Future of Printing

More than just equipment, the Automatic DTF Carousel Heat Press is a strategic partner for those seeking growth, scalability, and quality in printing processes.

This is just the beginning of a new era in product customization. Contact the Yguaçú Máquinas team and get to know up close this launch that will elevate your production level.