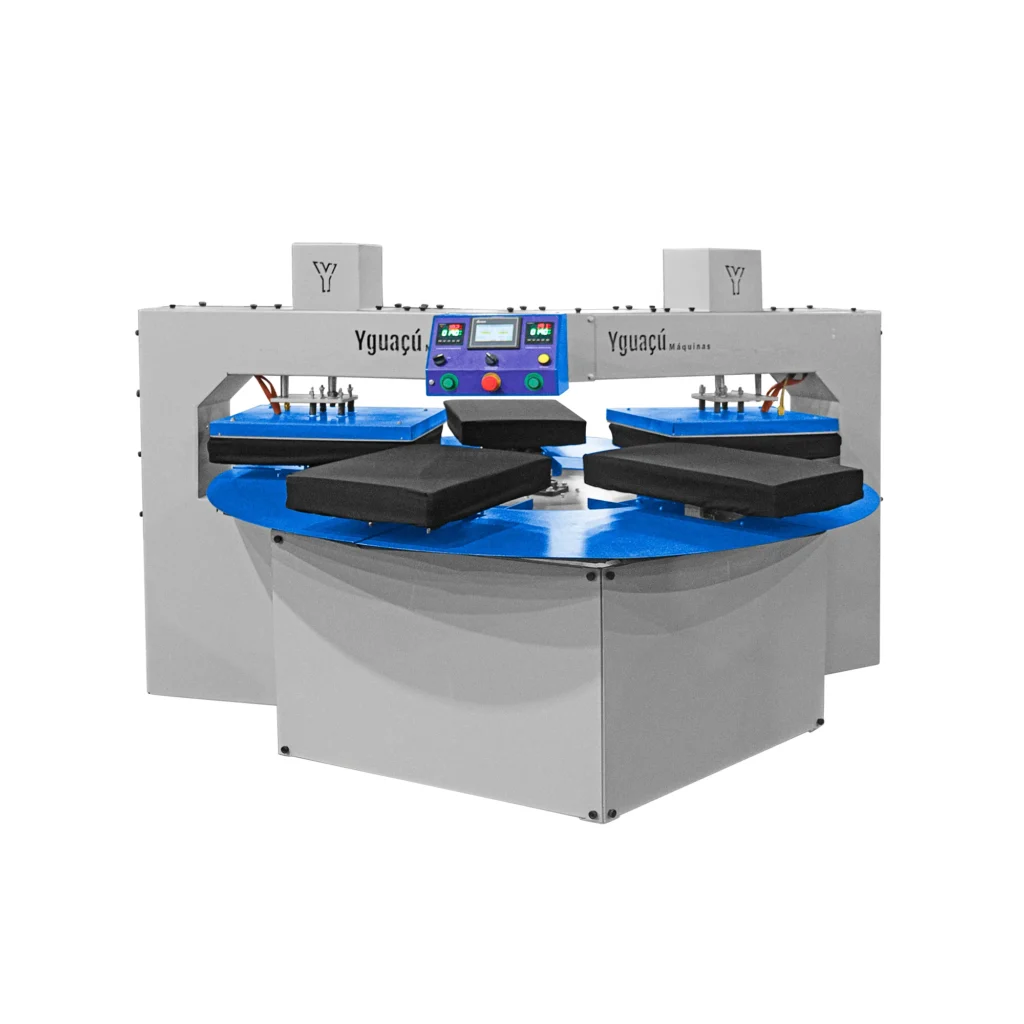

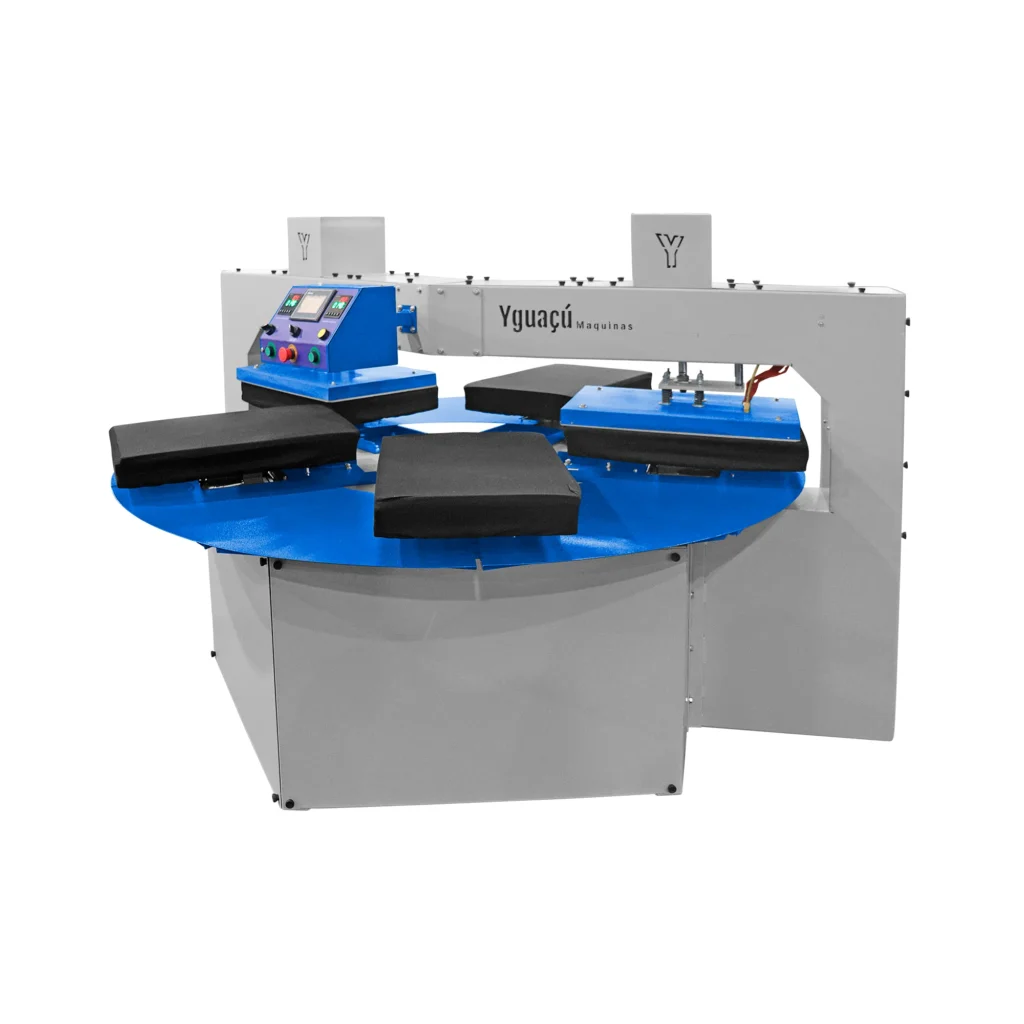

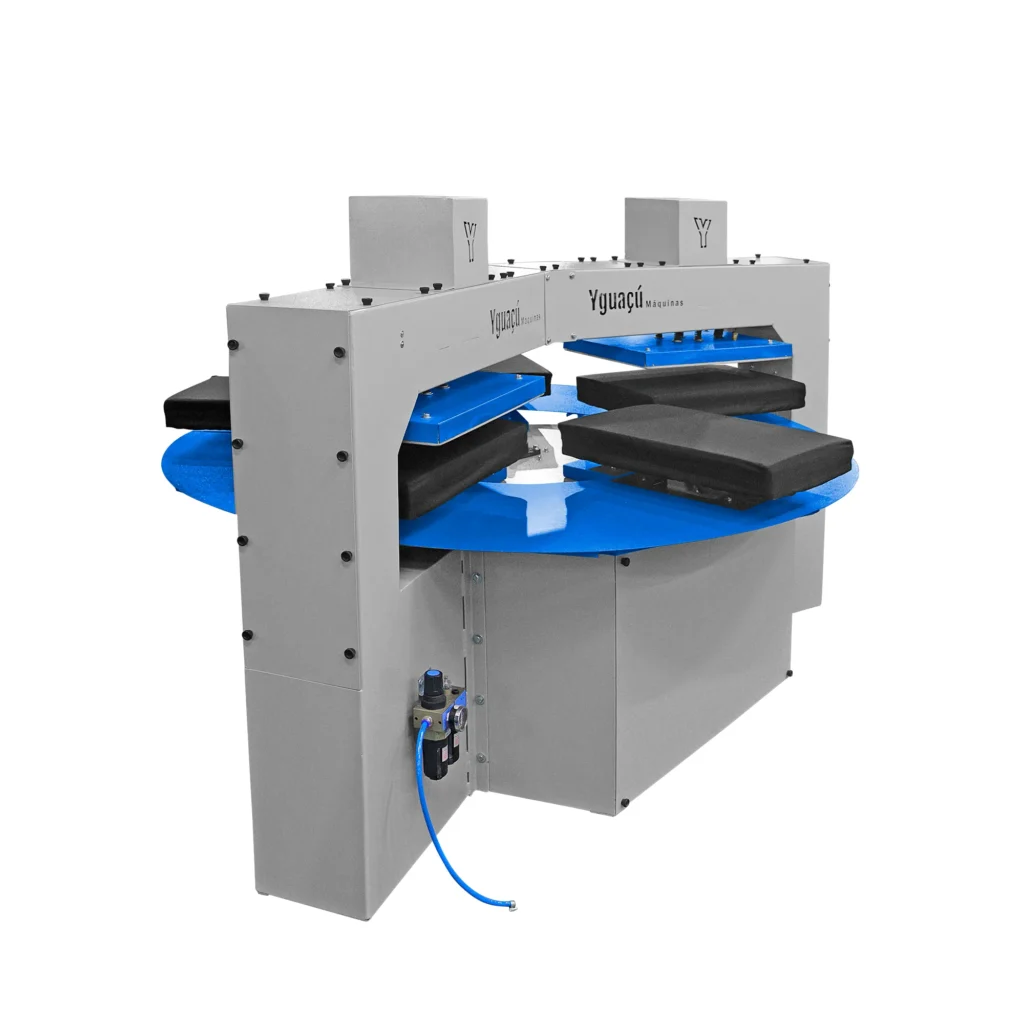

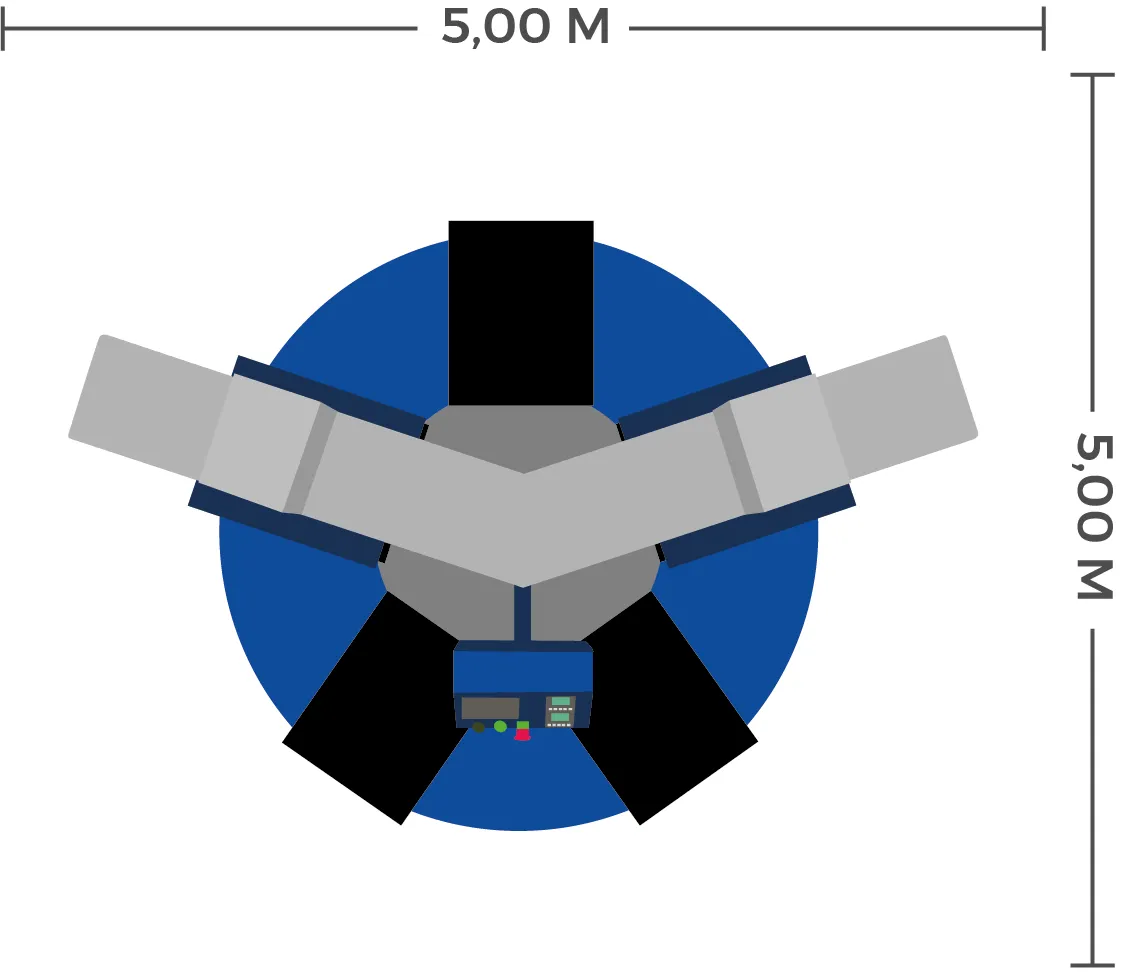

The Carrossel DTF Automatic Press is high-productivity pneumatic equipment, specially developed for the DTF (Direct to Film) process, but also compatible with sublimation, transfer, screen printing curing, and other types of thermal fixation. Its automatic rotation system, driven by an electric motor, offers greater agility, precision, and comfort in operation. With pneumatic operation (requiring a 10 psi/150 liter compressor, not included), the press features a carousel system with five positioning stations that facilitate continuous production flow.

The equipment has two independent and fully programmable aluminum heating platens for temperature and time, allowing printing areas of 40 x 50 cm or 50x70cm. The movement of the stations is done automatically by an electric motor, optimizing product changeover, while the touch screen display ensures ease of programming and use.

Its applications mainly include DTF, but also sublimation, heat transfer, screen printing curing, and other heat-setting techniques. In terms of productivity, the Carrossel DTF Automatic Press is capable of producing up to 360 pieces per hour in processes that require only one press per piece, or up to 180 pieces per hour in processes that require two presses.